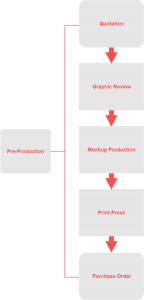

.Our production processes follow several common procedures. Certain items may require additional steps to achieve desired results, but our general methodologies remain consistent for all our projects.

| Pre-Production

Graphic Review Pre-production begins with our design engineering team reviewing the client’s graphic, ensuring all relevant and vital information are present for development. Optionally, our team could also revise and recommend potential areas of improvements. For further information on the design engineering services that Wictle provides, please visit our packaging options page.

Mockup Production A mock-up is constructed to test the integrity of the structure’s design – whether the design is practical when assembled. This stage is particularly important in ensuring the structural aspect of the packaging is functional, operable, and capable of protecting the product. Furthermore, clients can obtain initial feedback on the design direction, permitting room for adjustments before proceeding on to latter production stages.

Print-Press The print-press process constructs a substrate sample. The sample at this stage depicts all of the item’s graphic and color. This procedure enables color testing and contrast of a physical sample of the item in order to ensure hue consistency with the client’s request.

Quality Control Wictle conducts a variety of quality control tests in order to ensure the finished product is capable of withstanding potential damage from drops, temperature changes, pressure, scratches etc. Tests that we may conduct include:

Other Considerations If the final product incorporates coating or other production treatments, then the print-press sample will also receive the same treatment to ensure consistency.When our client-services, design and engineering team have given authorization, production can proceed. In order to avoid any inconsistencies during later stages, all teams must provide their own individual authorization before production can officially begin. |

|

|

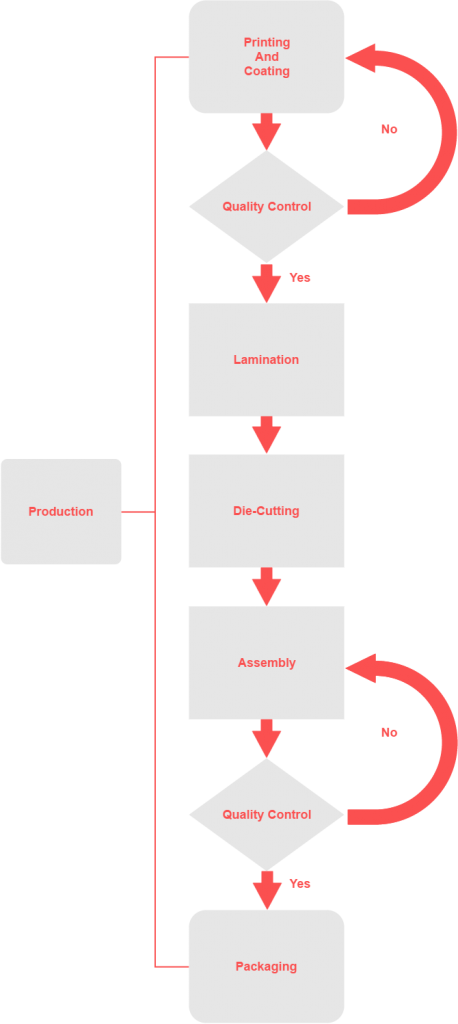

Production Printing and CoatingOnce our specialized teams have reviewed the samples and authorized production, our production team will begin printing in mass quantities. Our diversity of printing instruments enable the development of items with different size, length, materials and other aesthetic effects.

During this production stage, quality control is particularly important. Once the graphic is printed over a substrate, the process is irreversible. Defective products must be disposed of, generating waste. Therefore, to maintain our sustainability values, our staff utilizes various measuring tools to ensure consistency of our products with our client’s expectations. Coating, Embossing and other Treatment Printed items can also be treated at this stage to provide varying effects. The most commonly requested treatment include coating, a process which offers both protective and aesthetic qualities to the substrate and printed material. Other treatment processes may include embossing, whereby certain areas of the substrates (ex. text) are indented or “raised” to provide unique artistic qualities. At Wictle, we have the facilities available to provide unique attributes to your products.

Lamination Wictle’s utilizes specialized lamination facilities to fuse and bond layers together. Lamination is a chemical process that fuses the substrate to the base-layer, permanently binding both layers together. This process is vital for the development of packaging, since the base-layer provides the strength and sturdiness required for a packaging to assemble into shape and structure.

Base-Layer options Different base-layers possess different qualities, density and strength. Wictle provides a range of options for our clients to select, listing out the pros and cons of each selection. If our clients require stronger and sturdier packaging for heavier products, our consulting team may recommend the usage of packaging materials with damage resistant qualities such as corrugated paperboards.

Die-Cutting Our die-cutting process is handled by specialists, utilizing die-cutting instruments to maintain a high level of accuracy and precision.

Assembly and Quality Control Our highly trained staff provides the necessary finishing touches to complete the item. In addition to being a vital value-adding process, the assembly procedure also involves another team of quality control staff for inspection. Any defective items are identified and re-processed or disposed of.

Post-Production FeedbackOur dedicated CS team will provide follow-up services to ensure our client’s requests are met. The CS team will also seek feedback in order to ascertain potential areas of improvement, and how we can better service our clients in the future.

|

asdsa